the beautiful white Siberian tigress,

Sabrina

designed

and orchestrated by

Leslie Kiser

and woven by the designer,

as well as

a multitude of

tapestry students,

friends in need,

and casual passers-by

while under construction at Woolenworks

in McKinney, Texas, 1995-1998.

---o)(o---

A TIGRESS IN TEXAS

A Rare Creature Portrayed in a Rare Medium

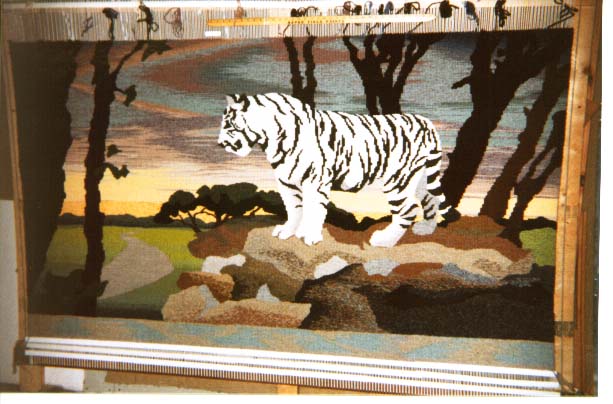

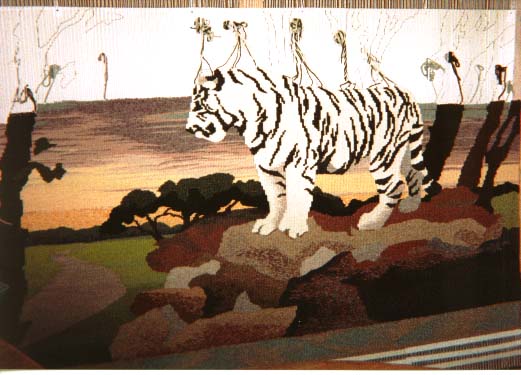

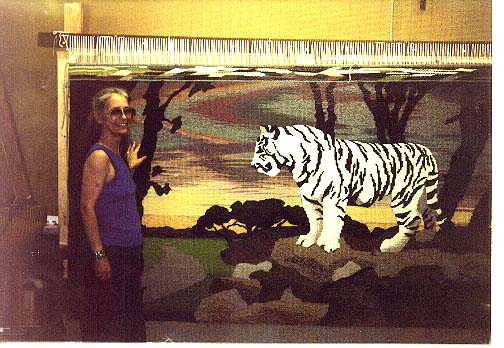

Above is the 7 1/2 by 4 foot handwoven tapestry, A Tigress in Texas, pictured still attached to its primitive loom.

You might wonder, "Why a SIBERIAN tiger in a NORTH TEXAS landscape?" While the main focus of this website is to document the construction of this weaving, it is hoped to also stimulate an awareness of the plight of many endangered species, as represented by the beautiful tigress, Sabrina of the Texas Exotic Felne Foundation.

---o)(o---

For most, the word "tapestry" conjures up images of drafty Medieval castles with monumental handwoven pictoral wall hangings. Many would be surprised to know that in our world of assembly-line mass-production, there still exists a small number of artisans dedicated to the creation of tapestries using the techniques perfected hundreds of years ago.

---o)(o---

---o)(o---

---o)(o---

But let's go back to the beginning.

The weaving starts at the bottom and at first we must sit on the ground. Outside, it's a typical Texas upper 90 degree plus summer, but the cement floor of Woolenworks in McKinney is amazingly cool.

---o)(o---

The loom consists of three vertical 2 x 4's, a diagonal to keep it "square", and two horizontal notched beams to hold the warp evenly spaced. (The warp is the white vertical string stretched tightly up and down between the horizontals that provides the foundation for the weaving.)

With seven feet of weaving width, there is elbow room for three weavers, although at times, the design forces one or more weavers to wait for an adjacent area to be completed before they can proceed, somewhat like laying bricks.

---o)(o---

As the weaving progresses we must elevate ourselves to the current working level by sitting on gradually taller pillows and chairs. Eventually we will stand on step stools to reach the highest areas.

If this were a more sophisticated (and expensive) loom, the weaving itself would be advanced to keep the working level even with the weavers, not unlike film in a camera.

However, I prefer this primitive frame loom for numerous reasons, the most important of which is that you can see the entire image area while you work, making subsequent design choices easier.

Otherwise, only a small section of the work is visible, making it necessary to continually "rewind" to view the progress or photograph the piece for reference as you go.

Here's the back of the tapestry. All the weaving has been completed and it has been cut from the loom, but there is still plenty of work to do.

All of the warp ends must be secured using the damascus knot. At 3 1/2 warp ends per inch (think pixels, if you're computer literate), that's 2940 warp ends and 2939 knots. And that's just the top!! There are just as many knots to tie on the bottom as well.

The top and bottom fold overs must be, .... ummmmh well .... , folded over to provide a firm, solid foundation for mounting on a horizontal board. Using not so ancient techniques involving velcro and (shudder) hot glue, the piece is truely finished and ready for installation.

This should provide some scale.

This link takes you to Bryan Livingston's Online Graphics Generator.